Cold air intake benefits are a crucial aspect of vehicle performance enhancement. This guide delves into the mechanics, benefits, and considerations associated with installing a cold air intake system in your car. Understanding the intricacies of these systems is key to making an informed decision about their potential impact on your vehicle.

Cold air intakes, by drawing in cooler, denser air, enhance engine performance by improving combustion efficiency. This, in turn, leads to noticeable gains in horsepower and torque, potentially making a noticeable difference in the vehicle’s overall driving experience. However, there are various factors to consider, including the specific vehicle type, installation methods, and potential impact on fuel economy and environmental considerations.

Introduction to Cold Air Intakes

Cold air intakes are performance modifications for internal combustion engines, aiming to enhance airflow and improve engine performance. They essentially redirect air intake to the engine, focusing on providing cooler air for combustion. This, in turn, can lead to improved power output, better fuel efficiency, and a more responsive engine.The fundamental principle behind a cold air intake is that cooler air is denser than warmer air.

Denser air contains more oxygen molecules, allowing for a more complete and efficient combustion process. This leads to greater power output and better fuel efficiency.

Components of a Cold Air Intake System

A cold air intake system typically comprises several key components. Understanding these components is crucial for a comprehensive understanding of how the system functions.

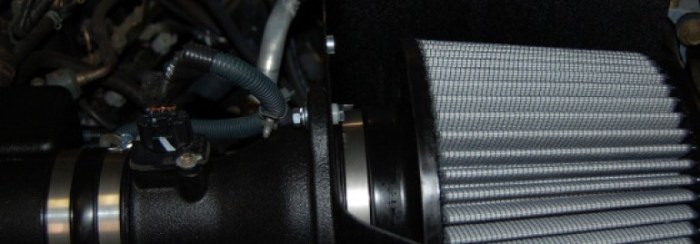

- Air Filter: This crucial component traps dirt and debris from entering the engine, preventing damage and ensuring optimal airflow. High-quality air filters are essential for longevity and performance.

- Intake Tube: A conduit that directs air from the filter to the throttle body. Intake tubes are often made of lightweight materials like aluminum or plastic to reduce weight and improve airflow.

- Cold Air Intake Box (or Enclosure): This houses the air filter and intake tube, creating a more efficient airflow path by directing cool outside air to the intake. The box is designed to minimize air turbulence and maintain optimal air temperature.

- Throttle Body: The throttle body is where the air and fuel mixture is controlled before entering the engine cylinders.

Diagram of Airflow

The following diagram illustrates the flow of air through a cold air intake system:

| Component | Description |

|---|---|

| Exterior Air | Ambient air, drawn from outside the vehicle. |

| Air Filter | Filters out dirt and debris from the incoming air. |

| Intake Tube | Channels the filtered air to the engine. |

| Intake Box (Enclosure) | Insulates the intake tube, directing cool air from the outside. |

| Throttle Body | Controls the flow of the air-fuel mixture into the engine. |

| Engine | The engine uses the air-fuel mixture for combustion. |

Imagine a simplified pathway: Outside air is drawn in, filtered by the air filter, channeled through the intake tube, and guided by the intake box to the throttle body, where it mixes with fuel before entering the engine for combustion. This streamlined flow path ensures optimal air delivery for enhanced engine performance.

Performance Gains & Improvements

Cold air intakes aim to enhance engine performance by optimizing the air delivery system. This involves improving the air’s density and temperature, directly impacting combustion efficiency and, consequently, power output. The measurable benefits, while often subtle, can be noticeable and worthwhile for many vehicle owners.The primary goal of a cold air intake is to provide the engine with denser, cooler air.

Denser air contains more oxygen, which fuels more complete combustion. Cooler air, in turn, contributes to a more efficient combustion process. These factors, in combination, can lead to tangible increases in horsepower and torque.

Measurable Performance Enhancements

Cold air intakes often result in noticeable performance gains, although the exact amount varies considerably based on the specific vehicle, intake design, and driving conditions. Experienced drivers and enthusiasts frequently report increases in acceleration and responsiveness, especially noticeable at higher RPMs.

Increase in Horsepower and Torque

Cold air intakes, by improving the density and temperature of the air entering the engine, facilitate a more complete combustion process. This increased efficiency leads to a noticeable increase in horsepower and torque, especially in higher-revving applications. For example, a well-designed cold air intake can yield a few horsepower gains, potentially improving the vehicle’s overall performance characteristics.

Air Density and Engine Performance

The density of the air directly impacts the amount of oxygen available for combustion. Denser air means more oxygen, leading to a more complete and efficient burning of fuel. This translates into more power output. A cold air intake, by drawing in cooler, denser air, increases the engine’s ability to extract more power from the same amount of fuel.

Higher air density is directly related to lower air temperature.

Impact of Intake Temperature on Combustion Efficiency

Warmer air is less dense than cooler air. This difference in density directly impacts the amount of oxygen available for combustion. Cooler intake air leads to more complete combustion, maximizing the energy extracted from the fuel. The higher the intake temperature, the lower the combustion efficiency and power output. A cold air intake mitigates this effect.

Comparison of Performance Gains from Various Designs

Different cold air intake designs offer varying levels of performance gains. Some designs incorporate a larger air filter or a more efficient air routing system. Others focus on directing the air more efficiently to the engine’s intake manifold. The specific design and materials used will affect the performance gains. A high-quality intake will result in a higher power output than a lower-quality intake.

However, quantifiable results depend significantly on factors like the vehicle’s engine characteristics, the ambient temperature, and the driving conditions. A properly tested and calibrated intake system is essential to determine the potential performance gains accurately.

Types of Cold Air Intakes

Cold air intakes are designed to improve engine performance by drawing in cooler air. Various types are available, each with its own set of features and trade-offs in terms of cost, installation difficulty, and potential performance gains. Understanding these differences helps in choosing the right intake for a specific vehicle and budget.Different designs aim to achieve the same goal: maximizing the amount of cool, dense air reaching the engine.

This cooler air allows for more efficient combustion, leading to increased horsepower and torque. The best choice depends on the vehicle’s specific needs and the desired level of performance improvement.

Types of Cold Air Intake Designs

Different intake designs cater to varying vehicle needs and performance expectations. Understanding these differences helps in selecting the most suitable intake for a specific application.

- Panel Filter Intakes: These intakes typically feature a large, panel-style air filter housing. The filter is often easily accessible for cleaning and replacement. A significant advantage is the usually straightforward installation process. This design frequently involves minimal modification to the vehicle’s existing air intake system.

- Cone Filter Intakes: These intakes employ a cone-shaped filter housing. They are designed to channel air directly to the engine. Their design sometimes allows for a slightly improved airflow compared to panel filter intakes, though this is not always significant. The installation process is usually relatively simple, but some minor adjustments to the vehicle’s existing components may be necessary. Cone intakes can offer a balanced approach between performance gains and installation complexity.

- Full-System Intakes: These intakes replace the entire stock air intake system. Full-system intakes often feature a custom-designed air box and piping to maximize air intake. These intakes typically yield the greatest performance gains but require significant modifications to the vehicle’s existing system, including fabricating and fitting custom parts. The complexity of installation can make it more costly and time-consuming than other options.

- Velocity Stack Intakes: These intakes are designed to improve airflow velocity to the engine. They typically feature a specialized air intake funnel, or velocity stack, which is designed to accelerate airflow. This feature can lead to a noticeable performance improvement. Installation is usually moderately complex, but the potential performance increase can justify the effort for some drivers.

Comparative Analysis of Intake Types

A table summarizing the key characteristics of different intake types helps in making an informed decision.

| Intake Type | Price | Installation Complexity | Performance Gains |

|---|---|---|---|

| Panel Filter | Moderate | Low | Minor to Moderate |

| Cone Filter | Moderate | Moderate | Moderate |

| Full-System | High | High | Significant |

| Velocity Stack | High | Moderate | Moderate to Significant |

The table above provides a general comparison. Actual price, installation complexity, and performance gains can vary depending on the specific intake model and vehicle application. Consider these factors when making your choice.

Installation Procedures & Methods

Installing a cold air intake system can significantly enhance your vehicle’s performance, but a meticulous approach is crucial for success. Proper installation ensures optimal airflow and avoids potential damage to your engine. This section details the necessary steps, tools, and safety considerations for a successful DIY installation, or when seeking professional assistance.Installing a cold air intake requires a methodical approach to ensure proper function and avoid potential issues.

Careful adherence to the manufacturer’s instructions is vital for achieving the intended performance gains.

Step-by-Step Installation Guide

This guide provides a general Artikel for installing a cold air intake. Specific procedures may vary based on the particular intake system and vehicle model. Always consult the manufacturer’s instructions for your specific model.

- Preparation: Thoroughly inspect the old air intake system for any damage or wear. Gather all required tools and materials. Clear a workspace to ensure easy access to the engine bay.

- Disassembly: Disconnect the old air intake system from the engine’s air intake. Carefully detach the old air filter and associated components, noting the connections for reassembly.

- Installation: Position the new cold air intake system in place, ensuring proper alignment with the engine’s air intake. Secure the intake system with the provided fasteners and brackets.

- Connection: Connect the new air intake tubing to the engine’s air intake. Double-check all connections for tightness and proper fit. Ensure that there are no kinks or obstructions in the intake tubing.

- Finishing Touches: Install the new air filter. Verify that all components are securely fastened and functional. Test the system to ensure there are no leaks or other issues.

- Verification: Start the engine and listen for any unusual noises. Inspect all connections and hoses for leaks. Ensure proper operation of the intake system.

Required Tools & Materials

A comprehensive list of tools and materials is essential for a smooth installation. This will ensure a correct installation process, and also ensure the safety of the person doing the installation.

- Screwdrivers (Phillips and flathead)

- Wrench set (appropriate sizes)

- Pliers

- Socket set

- Torque wrench (recommended)

- Gloves

- New air filter

- New intake tubing

- Fasteners and brackets (provided with the kit)

- Cleaning supplies (e.g., compressed air)

Safety Precautions

Prioritizing safety during installation is paramount. Following these precautions will protect the installer and the vehicle.

- Engine Shutdown: Ensure the engine is completely turned off and cooled before beginning any work.

- Vehicle Support: Use jack stands to securely support the vehicle to prevent any accidents.

- Protective Gear: Wear appropriate safety glasses, gloves, and other protective gear to prevent injuries.

- Electrical Safety: Disconnect the negative battery terminal to avoid any electrical hazards.

- Environmental Considerations: Work in a well-ventilated area.

DIY vs. Professional Installation

Choosing between DIY and professional installation depends on your comfort level and resources. Both methods have their advantages and disadvantages.

- DIY Installation: DIY installation offers a cost-effective approach. However, it requires meticulous attention to detail and a good understanding of vehicle mechanics.

- Professional Installation: Professional installation ensures a quality job by experienced technicians. It guarantees accuracy and potentially avoids costly errors.

Impact on Fuel Economy

Cold air intakes are often touted as performance enhancers, but their impact on fuel economy is a more nuanced discussion. While some enthusiasts report improved mileage, others find little to no change, or even a slight decrease. The truth is complex, and depends on several factors.The claimed benefits of a cold air intake often stem from the theory that drawing in cooler, denser air allows the engine to achieve a more efficient combustion process.

However, this assumes the engine is operating optimally and the intake system doesn’t introduce any other, offsetting factors.

Factors Influencing Fuel Economy Impact

Several factors contribute to the unpredictable effect of cold air intakes on fuel economy. Engine tuning, for example, plays a crucial role. A poorly tuned engine, or one not designed to accommodate the modifications made by the intake, might not experience any noticeable benefit, or even suffer a loss of fuel efficiency. Furthermore, the design of the intake system itself is important.

A poorly designed or installed system can introduce airflow restrictions or turbulence, leading to inefficiencies that counter the benefits of a cooler intake.

Varying Results from Studies and Tests

Empirical data on the fuel economy impact of cold air intakes is somewhat inconsistent. Some studies suggest marginal improvements in fuel economy, often in the range of a few percentage points. However, other tests reveal no significant change, or even a slight reduction in fuel efficiency. It’s crucial to remember that these results depend heavily on the specific vehicle, engine type, intake design, and testing conditions.

Types of Intakes and Their Impact

Different types of cold air intakes can have varying impacts on fuel economy. For instance, a high-flow intake that is properly installed and tuned to the engine can potentially result in minor improvements. However, a poorly designed or poorly installed system may not improve fuel economy or could even lead to a decrease. Factors such as the material used in the intake tube, the filter type, and the overall design will play a role in the observed effects.

Case Studies and Examples

While conclusive, large-scale studies on the subject are limited, real-world observations and anecdotal reports provide insights. For example, some owners of vehicles with high-performance intakes report no noticeable change in fuel economy. This is likely due to the fact that the increased engine performance is not balanced by corresponding improvements in fuel efficiency. Conversely, some owners report slight improvements, suggesting that the cooler air intake does contribute to improved combustion and therefore, slightly better fuel economy.

Analysis of Consistency

Cold air intakes do not consistently improve fuel economy. The outcome is not guaranteed. There are several factors that determine whether a cold air intake will improve or worsen fuel economy, and it is not possible to make a general statement that applies to all vehicles.

Maintenance & Longevity

Cold air intakes, while enhancing performance, require specific maintenance to ensure their longevity and continued effectiveness. Proper care and attention to potential issues can significantly extend the life of your intake system, preventing costly replacements and maintaining optimal performance.Maintaining a cold air intake involves more than just visual inspection. Understanding the potential lifespan of various systems, and the factors impacting it, helps owners make informed decisions about upkeep and potential replacements.

Proper preventative measures and a proactive approach to maintenance are key to maximizing the lifespan and effectiveness of the intake.

Maintenance Requirements

Regular cleaning and inspection are crucial for optimal cold air intake performance and longevity. Dirt, debris, and insects can accumulate inside the intake system, restricting airflow and impacting performance. This accumulation can also lead to potential damage over time. Visual inspection should be conducted regularly to identify any signs of damage or deterioration. Cleaning the intake system should be performed periodically, following the manufacturer’s recommendations.

This often involves removing the intake and cleaning it with compressed air or mild detergent.

Potential Lifespan

The lifespan of a cold air intake system varies significantly depending on several factors, including the quality of materials, the environmental conditions, and the frequency of maintenance. High-quality intakes constructed from durable materials like aluminum or carbon fiber tend to have a longer lifespan compared to intakes made of less robust materials. A properly maintained intake system can last for several years, often exceeding the life of the vehicle’s original components.

However, factors like exposure to harsh weather conditions, frequent use in dusty environments, or a lack of proper maintenance can significantly shorten the lifespan.

Factors Affecting Longevity

Several factors can negatively impact the longevity of a cold air intake system. Environmental conditions play a significant role. Exposure to extreme temperatures, moisture, and dust can accelerate deterioration. Driving in dusty environments or in areas with high levels of particulate matter can lead to rapid clogging of the intake system, requiring more frequent cleaning. Furthermore, the quality of the materials used in the intake system is critical.

Low-quality materials may degrade faster, leading to a shorter lifespan. Lastly, neglecting proper maintenance practices, such as infrequent cleaning or failing to address any signs of damage, will significantly decrease the intake’s longevity.

Preventing Damage

Preventing damage to a cold air intake system is crucial for extending its lifespan and maintaining performance. Regular cleaning, as mentioned earlier, is a vital preventative measure. Inspecting the intake system for any signs of damage, such as cracks, leaks, or deformation, is equally important. Protecting the intake from harsh environmental conditions, such as extreme temperatures and moisture, can also extend its lifespan.

Driving in dusty environments or areas with high particulate matter should be addressed with appropriate protective measures, such as using a high-quality air filter or taking extra precautions when driving.

Cost Analysis & Return on Investment: Cold Air Intake Benefits

A cold air intake, while often touted for performance gains, is a significant investment. Understanding the cost implications and potential return on investment (ROI) is crucial for making an informed decision. This section delves into the cost structure of various intake systems, the factors that influence their pricing, and how to evaluate the ROI based on potential performance improvements.

Cost Breakdown of Cold Air Intakes

Different cold air intakes vary significantly in price, reflecting the materials used, design complexity, and features incorporated. Factors like the construction materials (aluminum, plastic, or a blend), the level of filtration (e.g., high-flow filters), and the overall design (e.g., a complete intake system versus a simple filter replacement) contribute to the price difference. The manufacturer’s reputation and brand recognition can also impact the cost.

Factors Affecting Intake System Prices

Several factors contribute to the price range of cold air intakes.

- Material Quality and Construction: Higher-quality materials like aluminum or specialized alloys often lead to more durable and potentially more efficient intakes, resulting in a higher price point.

- Design Complexity: Intakes with intricate designs, such as those featuring specialized shrouding or ducting, are often more expensive due to the increased manufacturing complexity.

- Filter Type and Performance: High-flow filters, often constructed from materials like oiled cotton or synthetic blends, typically offer improved air intake and are more expensive than standard filters.

- Brand Recognition and Reputation: Established brands with a history of quality and performance typically command a higher price compared to less recognized manufacturers.

- Additional Features: Some intakes incorporate additional features like pre-filters or heat shields, which contribute to the overall cost.

Return on Investment (ROI) Considerations, Cold air intake benefits

Determining the ROI of a cold air intake requires careful consideration of potential performance gains against the installation cost. The expected gains will depend on the vehicle’s model, the specific intake system, and driving conditions. While some may see noticeable improvements in acceleration and responsiveness, others may experience minimal or insignificant changes. A thorough cost-benefit analysis, considering the intake’s cost and potential improvements, is essential for a realistic evaluation of ROI.

Comparative Cost Analysis of Different Intakes

The following table provides a general comparison of potential costs and associated performance gains across different intake types. Keep in mind that these are estimations and real-world results may vary.

| Intake Type | Estimated Cost (USD) | Potential Performance Gains (Estimated) |

|---|---|---|

| Basic Filter Replacement | $50-$150 | Minor improvements in responsiveness, typically less than 5% |

| Intermediate Cold Air Intake System | $150-$300 | Moderate improvements in responsiveness and horsepower, typically 5-10% |

| Premium Cold Air Intake System | $300-$600+ | Significant improvements in responsiveness and horsepower, potentially exceeding 10% |

Note: Performance gains are estimates and can vary greatly based on the vehicle, driving conditions, and the specific cold air intake system.

Environmental Considerations

While cold air intakes can enhance performance, their environmental impact warrants careful consideration. Optimizing performance often involves trade-offs, and the environmental footprint of these modifications should be weighed against the potential gains. Understanding the potential positive and negative effects helps consumers make informed choices.Cold air intakes, though often perceived as performance-enhancing, can introduce certain environmental concerns. These range from the material composition and manufacturing processes to the potential impact on fuel economy, which, in turn, influences emissions.

Material Composition and Manufacturing

The environmental impact of a cold air intake is intricately linked to the materials used in its construction. Different materials have varying carbon footprints, and the manufacturing processes themselves can contribute to pollution. For instance, intakes made from aluminum typically have a lower carbon footprint than those made from stainless steel. Further, recycled materials reduce the environmental burden compared to virgin materials.

- Aluminum intakes generally have a lower carbon footprint compared to stainless steel due to the energy intensity of aluminum production. However, the recycling process for aluminum also plays a critical role in reducing the overall impact.

- Polymers, such as those used in some intake designs, can have varying levels of environmental impact depending on their specific composition and the manufacturing processes involved. Recycled polymers offer a more sustainable option compared to those derived from virgin materials.

- Stainless steel, a commonly used material, carries a higher carbon footprint compared to aluminum. The production process of stainless steel consumes significant energy and often involves the release of greenhouse gases.

Impact on Fuel Economy

While cold air intakes are often advertised as increasing horsepower, their effect on fuel economy is not always straightforward. In some cases, the performance gains might be marginal or even negated by increased fuel consumption. This, in turn, affects the overall environmental impact.

Improved airflow might not always lead to better fuel efficiency. Increased engine load, in some cases, might offset any potential gains.

The net effect on fuel economy depends on several factors, including the vehicle’s design, the specific intake design, and driving conditions.

Design Considerations

The design of a cold air intake significantly influences its environmental impact. Certain designs might be more energy-efficient to produce and less detrimental to the vehicle’s fuel economy.

- High-quality, well-engineered intakes are more likely to lead to better fuel economy. This involves considerations such as proper airflow channeling and material selection.

- Intakes with complex geometries or large air filters might increase the vehicle’s overall weight, leading to potential fuel consumption issues.

- Some intake designs prioritize aesthetics over functionality, potentially resulting in a higher environmental cost due to the increased complexity and materials involved in production.

Carbon Footprint Analysis

A precise calculation of the carbon footprint of a cold air intake is complex. It depends on the manufacturing process, material type, transportation, and end-of-life disposal. Comparative analysis is usually not readily available due to the varied components and manufacturing methods involved.

- The carbon footprint of a cold air intake varies significantly depending on the materials used, the manufacturing process, and the design. Direct comparisons often lack the necessary granular data.

Compatibility & Fitment

Ensuring a cold air intake’s compatibility with your vehicle is crucial for optimal performance and a smooth installation process. Incorrect fitment can lead to significant issues, from compromised airflow to potential damage to your engine bay. Proper compatibility guarantees the intake will function as intended, maximizing the benefits of the upgrade.Proper compatibility is determined by matching the intake’s design to the specific vehicle’s engine bay configuration.

This includes factors like engine type, year, make, and model. A thorough understanding of these specifications is paramount for a successful installation.

Vehicle Compatibility

Identifying compatible vehicles for a particular cold air intake model is essential for avoiding unnecessary purchases and ensuring the correct fit. Manufacturers typically provide detailed compatibility guides on their websites. These guides usually list specific vehicle years, makes, and models that are compatible with the intake. It is important to cross-reference this information with your vehicle’s specifications to avoid potential compatibility issues.

Fitment Importance

Proper fitment is critical for several reasons. Firstly, a correctly fitted intake ensures the optimal flow of air into the engine, maximizing performance gains. Secondly, a well-fitted intake reduces the risk of leaks, which can compromise engine performance and fuel efficiency. Thirdly, a properly fitted intake contributes to the overall durability of the intake system, preventing potential damage over time.

Potential Issues with Improper Fitment

Improper fitment can lead to a variety of issues, including reduced performance, increased fuel consumption, and even potential damage to the vehicle’s engine components. For example, a poorly fitted intake might allow air leaks, causing the engine to operate less efficiently and consume more fuel than expected. Furthermore, if the intake doesn’t fit correctly, it could rub against other engine components, potentially causing damage.

It’s crucial to follow the manufacturer’s installation instructions meticulously to minimize these risks.

Example Compatibility Guide (Hypothetical)

| Cold Air Intake Model | Compatible Vehicles |

|---|---|

| “Apex Performance CAI-1000” |

|

| “Velocity Racing CAI-2000” |

|

Note: This is a hypothetical example. Always refer to the manufacturer’s official compatibility guide for accurate information.

Potential Drawbacks & Limitations

While cold air intakes can enhance engine performance in many vehicles, there are potential drawbacks and limitations to consider. These factors can impact overall efficiency, safety, and the expected benefits. Careful consideration of these limitations is crucial before installation.Incorrect installation can lead to detrimental consequences for performance and longevity. Proper installation is essential for optimal performance.

Performance Issues with Incorrect Installation

Improper installation of a cold air intake can hinder performance gains, rather than enhancing them. Incorrect placement, improper sealing, or insufficient air routing can restrict airflow, resulting in reduced horsepower and torque output. This is often more pronounced in vehicles with intricate engine bays or complex intake systems. Furthermore, the added air filter and piping can create additional restrictions, diminishing the benefits of the intake.

A poorly installed system can even cause reduced fuel efficiency.

Sound and Vibration Issues

The addition of a cold air intake can sometimes introduce noticeable sound and vibration changes to the vehicle. The increased airflow and different air filter can result in a louder intake sound, especially under acceleration. This amplified sound can be noticeable to the driver and passengers. Similarly, some designs can contribute to increased engine noise or vibration levels.

Cold air intakes are often touted for improving engine performance, but their effectiveness can vary. Recent car news articles, like those found on Car news , highlight the nuances of these modifications. Ultimately, the benefits of a cold air intake are dependent on factors like the specific vehicle and its current setup. A well-chosen intake can definitely enhance the engine’s response, but it’s not a guaranteed magic bullet.

While these issues are usually minor, they are important considerations for some drivers who value a quiet driving experience.

Cold air intakes are often touted for boosting engine performance. Recent Tesla news, like the ones available at Tesla news , highlights how various upgrades can affect vehicle efficiency. Ultimately, though, the key benefit of a cold air intake is generally a slight increase in horsepower and torque, and better overall engine response.

Limitations in Performance Gains with Some Vehicles

Performance gains from a cold air intake are not uniform across all vehicles. The magnitude of performance enhancement varies depending on the vehicle’s specific engine characteristics, existing intake system, and overall tuning. Some engines, especially those with advanced engine management systems, might not experience substantial performance gains. Vehicles with already optimized intake systems may not see a noticeable increase.

Additionally, other performance modifications, such as exhaust systems or engine tuning, may have a greater impact on the vehicle’s performance than a cold air intake alone. For instance, some vehicles with highly restrictive stock intake systems may experience more significant performance gains than those with less restrictive setups.

Visual Representation & Examples

Visualizing a cold air intake system provides a clear understanding of its design and components. This section details the key features of a high-performance system, illustrating the differences between various types, and offering a practical table for comparison. A thorough understanding of these visual aspects is crucial for selecting the right intake system for your vehicle and maximizing its performance.

High-Performance Cold Air Intake System

A high-performance cold air intake system is designed to improve airflow to the engine. A key component is a high-flow air filter, typically made of a dense, yet porous material. This material allows for maximum airflow while trapping dirt and debris, ensuring the engine receives clean air. The intake tube itself is often constructed from a lightweight, yet strong material like aluminum or carbon fiber, to minimize weight and maximize airflow.

The system is often fitted with a cone or other carefully designed shape to funnel the air into the engine with maximum efficiency. These intakes often feature a heat shield to minimize the intake temperature rise.

Visual Representation in Action

Imagine a detailed illustration of a high-performance cold air intake system. The drawing would show the air filter housed within a custom-designed air box. A large, lightweight intake tube would be visible, leading from the air box to the throttle body. The tube would be routed through the engine compartment, possibly featuring heat shields or other thermal management components.

The illustration would clearly depict the airflow path from the filter to the engine, highlighting the streamlined design of the intake. The visual would also show the difference in air intake path and the reduction in restriction compared to a standard intake.

Visual Differences Between Intake Types

Different cold air intake systems vary in their design and components. A simple, open-element intake system, often using a large filter element directly exposed to the surrounding air, can be visually distinct from a more elaborate, sealed box intake, designed to improve airflow and temperature regulation. The use of heat shields, different tube materials, and varying filter elements are all visual cues indicating different performance characteristics and expected performance outcomes.

Comparison Table of Cold Air Intake Systems

| Intake Type | Image Description | Key Features |

|---|---|---|

| Open-Element | An open-element intake system typically exposes the filter directly to the surrounding air. This is often visually apparent by the filter’s placement, without a housing or enclosure. | Simplicity, cost-effectiveness, potentially more exposed to contaminants. |

| Sealed Box | A sealed box intake system encloses the filter in a custom-designed air box, providing a more controlled airflow path. | Improved airflow efficiency, reduced intake air temperature, better protection from contaminants. |

| Cone-style | A cone-style intake system utilizes a cone-shaped intake tube to direct the air into the engine. | Improved airflow efficiency, reduced restriction, often seen with high-performance systems. |

| High-Flow Filter | A high-flow air filter is often made of a material that offers higher airflow, allowing more air to reach the engine, usually visible in the air box. | Increased airflow, better performance, potentially a higher price point. |

Outcome Summary

In conclusion, cold air intakes offer potential performance enhancements, but careful consideration of various factors, including cost, compatibility, and potential drawbacks, is essential. Ultimately, the decision to install a cold air intake depends on individual needs and priorities. This guide has provided a comprehensive overview to help you make an informed choice.

Clarifying Questions

What are the common materials used in cold air intake systems?

Common materials include aluminum, plastic, and sometimes carbon fiber, each with its own advantages and disadvantages related to cost, durability, and aesthetic appeal.

Can a cold air intake damage my engine?

Incorrect installation or using an incompatible intake can potentially damage your engine. Proper installation is crucial.

How much does a cold air intake system typically cost?

Costs vary widely depending on the type, brand, and specific vehicle. Research different brands and compare prices before purchasing.

What are the typical performance gains from installing a cold air intake?

Performance gains are not standardized and vary based on factors such as the vehicle’s existing engine tuning and the specific design of the intake.